Introduction

The creation and consumption of material goods constitutes the main purpose and essence of economic activity, in which the financial environment, services and spiritual goods are only tools and levers to increase the level of economic-social performance and the quality of life by creating added value. The evolution of the world economy shows us how important it is to develop productive capacities, industry being the driving force of society’s prosperity.

The obtaining of material goods by the combination of economic factors is conditioned by the quality of the central pillar in this process – the human resource. In the context of economic globalization and international migration, the issue of ensuring industrial enterprises with sufficient and qualified human resources has become imperative. The Republic of Moldova is increasingly facing the shortage of personnel in industry, a branch that contributes about 22% to the formation of the Gross Domestic Product (UNECE Data Portal, 2024). Between 2014 and 2022, the country’s population decreased by about 354.6 thousand people, from 2.869.2 thousand in 2014 to 2.512.8 thousand in 2022 (NBS, 2023a), or by 12.42%, while annual emigration (including travel, studies and work, permanent emigration) has almost doubled (196.37%) from 122.955 emigrants in 2014 to 241.448 emigrants in 2022 (NBS, 2024e). This dynamic shows us the difficulty of business development in the conditions of a constant reduction in the labour supply. Consequently, the issue of replacing work force with machinery and technical equipment has taken on a new connotation, that of compensating for the shortage of employees.

At the same time, human activity has reached a point where the price at which we develop the values and potential that will be passed on to future generations is being reconsidered, with a view to the sustainability of human activity.

Sustainable development is a concept that first appeared in 1987 with the publication of the Brundtland Report (United Nations Organisation, 1987), warning of the negative environmental consequences of economic growth and globalization, and attempting to find possible solutions to the problems caused by industrialization and population growth.

As a continuation of this desire comes the “Industry 4.0” initiative, presented for the first time in 2011 at the Hannover Messe exhibition and which presents the concept of the German Federal Government’s High Tech Strategy (Deutche Masse, 02.04.2014), where digitization and automation of industrial processes are seen as solutions to boost sustainable industrial development, based on the use of information technologies and artificial intelligence, thus replacing the exploitation of human resources in various technological segments and industrial operations, including those with increased risks to employee health and safety.

In the context of a declining active population, national policymakers must find solutions to ensure the continuous and sustainable development of the Republic of Moldova’s industry, and the purpose of our research was to argue the reason to implement systems and technologies designed in the “Industry 4.0” paradigm in the Republic of Moldova.

Applied research methods and materials

In order to find the answer to the problem addressed and achieve the goal of the research, official statistical data were consulted, collected, selected and analysed (National Bureau of Statistics of the Republic of Moldova (NBS), UNECE Data Portal, National Employment Agency (ANOFM) )), relating to the number of the population, migration, the volume and indices of industrial production, the number of employees in the industrial branches. The results of the data analysis allowed to identify the discrepancy between the current and comparative indicators.

We also studied the opinions of researchers and practitioners regarding the prospects for sustainable industrial development and the impact of “Industry 4.0” systems and technologies on labour productivity. In this context, documents on the prospects for the dynamics of the labour market presented by international organizations (United Nations Organisation, World Economic Forum, PricewaterhouseCoopers, Bloomberg) and the Republic of Moldova (ANOFM, Expert-Grup), as well as the National Industrial Development Program for 2024-2028, approved by the Government of the Republic of Moldova, have been studied too.

Obtained results and discussions

Productivity from an economic point of view is a synthetic expression of the efficiency of using production factors in activities that result in economic goods. Being expressed as the ratio of the obtained economic result to the used production factor, valued in physical or monetary terms, labour productivity (W=Q/L) shows the efficiency of using human resource and the impact of labour on the economic result of the enterprise.

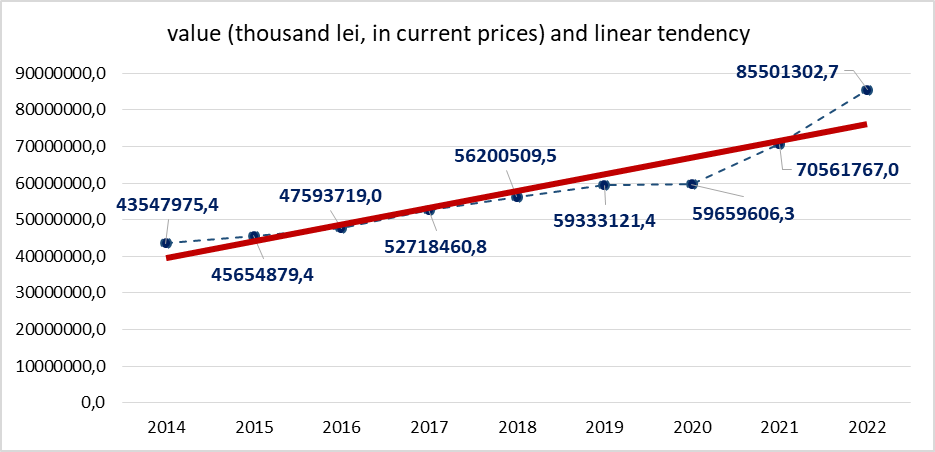

In the Republic of Moldova, the value of manufactured industrial products (in current prices) in 2022 amounted to 85,5 billion lei, which is 94,9% in comparable prices compared to 2021. The largest share in total manufactured industrial production is held by manufacturing industry (86,2%), followed by production and supply of electricity and heat, gas, hot water and air conditioning (10,2%), water distribution; sanitation, waste management, decontamination activities (2,1%) and the extractive industry (1,5%) (NBS, 2023b). The dynamics of the data from the period 2014-2022 show a constant growth of the country’s industrial sector (Figure 1). Thus, the value of manufactured industrial production, in current prices, in the period 2014-2022 increased from 43,54 billion lei in 2014 to 85,50 billion lei in 2022, representing a growth of about 196%.

Figure 1. Value of manufactured industrial production, 2014-2023

Source: compiled by the author based on (NBS, 2024a)

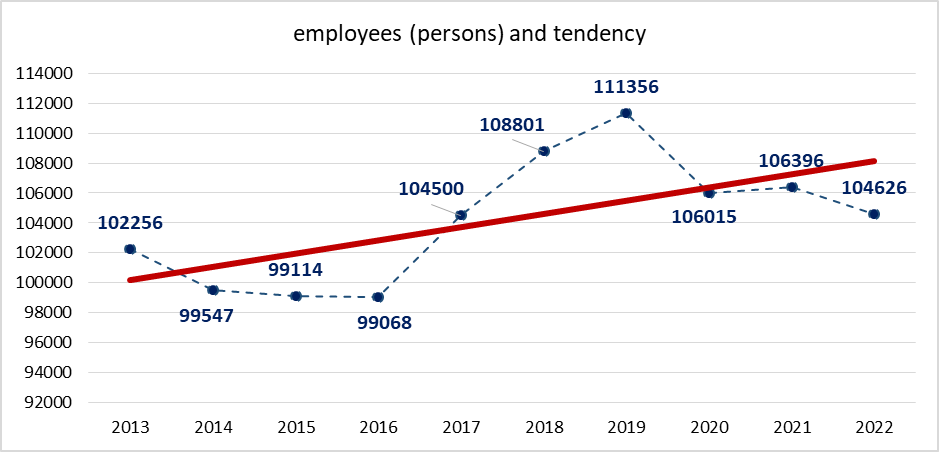

Similarly, despite the fluctuations recorded in the last 10 years, there is a tendency to increase the average number of employees in the industry (Figure 2), mainly due to the opening of new large-scale foreign-invested factories producing wiring harness systems for the automotive industry (Drarxlmaier Group, Fujikura Automotive, Sumitomo Electric Bordnetze). Specially, namely the decline in turnover of these companies, during the COVID-19 pandemic (2019-2021) and the post-pandemic economic consequences which led to a global decline in automobile production (2021-2023), had a great impact on the number of employees in the industry. Even in 2023 “nearly a third of major passenger-car plants from Europe’s five largest automakers – BMW, Mercedes-Benz, Stellantis, Renault and VW – were underutilized …, producing fewer than half the vehicles they have the capacity to make” (Nicola S., Torsoli A., Fevrier T. and Pogkas D. in Bloomberg, September 11, 2024).

Figure 2. The Republic of Moldova INDUSTRY. Average number of employees, both sexes (in full-time equivalent), 2013-2022, persons

Source: compiled by the author based on (NBS, 2024b)

At the same time, during this period a stable growth in average labour productivity, also expressed in current prices, is also observed (Table 1).

Table 1. Average productivity per employee in Moldovan industry,

in current prices, thousand lei

| 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | |

| Value of manufactured industrial production, billion lei (in current prices) | 43,54 | 45,65 | 47,59 | 52,71 | 56,20 | 59,33 | 59,65 | 70,56 | 85,50 |

| Average number (in full-time equivalent), persons | 99547 | 99114 | 99068 | 104500 | 108801 | 111356 | 106015 | 106396 | 104626 |

| Average productivity per employee, thousand lei (in current prices) | 437,46 | 460,63 | 480,41 | 504,48 | 516,54 | 532,82 | 562,75 | 663,20 | 817,21 |

Source: compiled by the author based on (NBS, 2024a) and (NBS, 2024b)

So, if we’ll take into account only the indicators estimated in current prices, then it appears that the challenges of the COVID-19 pandemic and the post-Covid economic effects did not have any negative impact on the average labour productivity, presented in Table 1.

Based on the research carried out, we concluded that, during the analysed period, the growth of average labour productivity in Moldova’s industry is mainly based on the increasing of manufactured products prices.

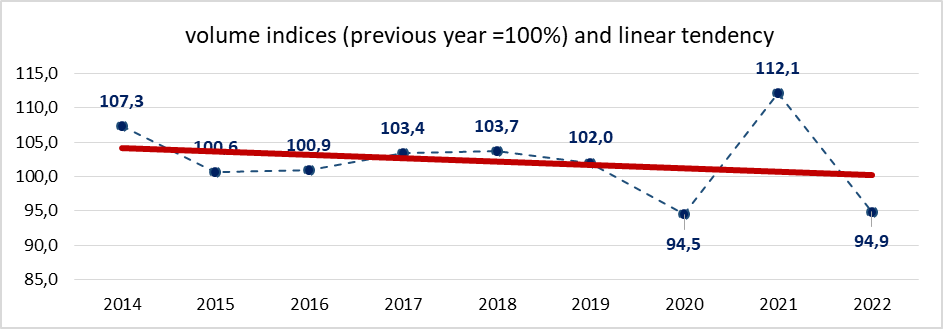

Although the data presented above shows us positive dynamics, the volume indices of industrial production compared to the previous year (previous year=100) shows us a different situation. Thus, compared to the previous year’s indicators, in the period 2014-2022. the index of the volume of industrial output recorded a negative trend (Figure 3).

Figure 3. Volume indices of industrial production, previous year =100%

Source: compiled by the author based on (NBS, 2024c)

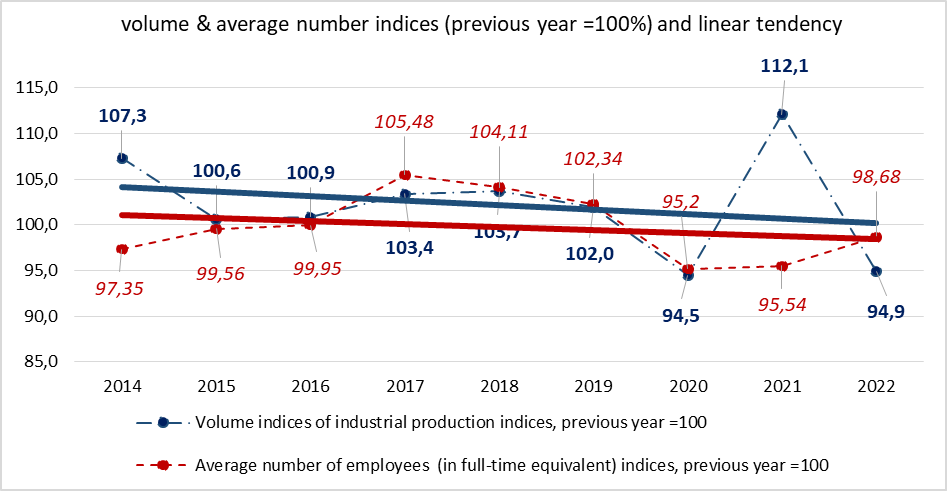

Continuing this logic, if we determine the indices of average number of employees in the industry of the Republic of Moldova compared to the previous year (previous year=100), it follows that in the period 2014-2022 it grew by only 1,33%, that is from 97,35% in 2014 to 98,68% in 2022 (Table 2).

Table 2. Indices of average number of employees in Moldova’ industry,

previous year =100%

| 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | |

| Average number of employees (in full-time equivalent), persons | 99547 | 99114 | 99068 | 104500 | 108801 | 111356 | 106015 | 106396 | 104626 |

| Indices of average number of employees in Moldova’ industry, previous year =100% | 97,35 | 99,56 | 99,95 | 105,48 | 104,11 | 102,34 | 95,20 | 95,54 | 98,68 |

Source: compiled by the author based on (NBS, 2024b)

Linear trends of “volume indices of industrial production” and “indices of average number of employees” in Moldova’ industry (previous year =100%), reveal that both indicators have a decreasing trend (Figure 4).

Figure 4. Linear relation of “volume indices vs average number of employee (in full-time equivalent) indices” of industrial production, previous year =100%

Source: compiled by the author based on (NBS, 2024c) and (NBS, 2024b)

Knowing that productivity is the ratio between the quantity of manufactured products and the number of workers who produced them (W=Q/L), we see that the trends presented in Figure 4 reveal a decreasing dynamic of labour productivity in the industry of the Republic of Moldova.

The demographic situation in the Republic of Moldova, as well as the opinions of experts in the field, entrepreneurs and industrial managers of the Republic of Moldova indicate the persistence of the problem of labour shortage in industrial enterprises of our country. Thus, according to the medium-term labour market forecast (2024-2026), developed by the Independent Analytical Centre “Expert-Grup”, “in the medium term, employment growth will be accompanied by an increase in labour shortage. The demand for labour will grow rapidly, and the supply of labour will have an anaemic evolution” (Expert-Grup, 2023, p. 16)

Same, according to the “Labour Market Forecast for 2023 from the Employers’ Perspective” developed by the National Employment Agency (ANOFM, 2023), in 2022, compared to 2021, there was a twofold increase in the number of economic agents who cited that the lack of qualified personnel and the low number of staff are one of the main reasons for the failure to fill vacant positions and full-time positions. The Forecast notes that the manufacturing industry has become the second industry most affected by the labour shortage (14%), after wholesale and retail trade.

The shortage of skilled and unskilled labour is a structural problem of the economy of the Republic of Moldova and, in particular, of the domestic industry. In general, the increase in the total number of people employed in industry over the past ten years has been due to the development of labor-intensive industries. At the same time, employment has sharply decreased in such industries as: production of electrical equipment (-68% compared to 2014), energy (-14%), footwear and leather industry (-26%), car repair and installation (-44%), beverage production (-9%), electronics production (-39%), metallurgy (-74%), etc. The reasons for this decrease were the closure of enterprises due to various crises (financial and banking, pandemic, war in the neighbouring country Ukraine, etc.), the withdrawal of foreign investors from the Moldovan market, as well as the introduction of new technologies (National Industrial Development Program for 2024-2028).

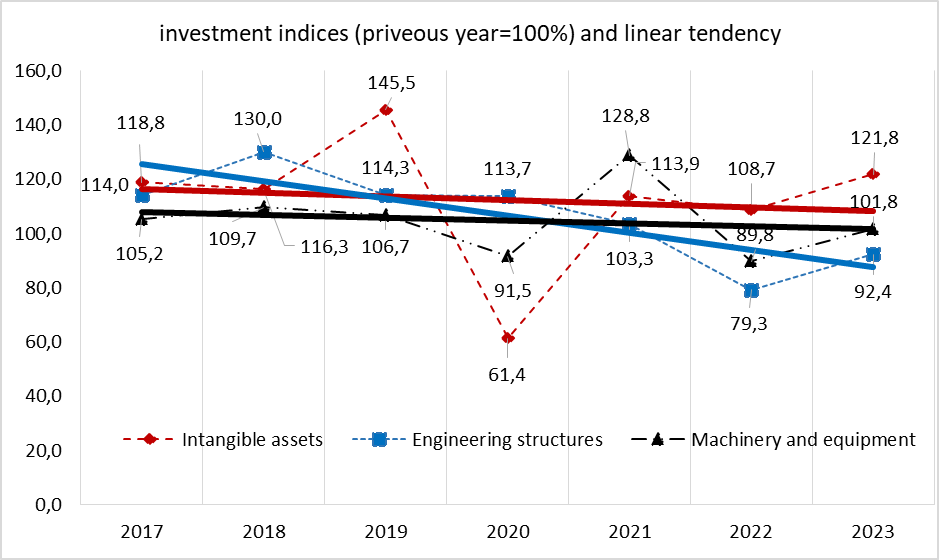

At the same time, the investment indices in the development of tangible productive technological potential (engineering structures, machines and equipment) and intangible assets (technologies, know-how) demonstrate that the decrease in labour productivity is primarily caused by these components (Figure 5).

Figure 5. Investments in non-current assets by types of assets, 2017-2023, in percent to the previous year (in comparable prices)

Source: compiled by the author based on (NBS, 2024d)

The trend lines of the three indicators in Figure 5 show a negative trend of investment preconditions that increase productivity and, respectively, demonstrate to us the causes of the reduction of real productivity (per real unit of output) in the Moldovan industry. Thus, taking into account the forecasts of the evolution of demand and supply in the labour market (ANOFM, 2023; Expert-Grup, 2023), it is expected that the decrease in labour productivity in the industry of the Republic of Moldova will continue.

Based on the analyses and research carried out, we consider that as a solution to stimulate the productive forces in the Republic of Moldova can be the Industry 4.0 paradigm, which refers to the technological transformation that society is experiencing in the 21st century (Ross & Maynard, 2021) and which involves a new approach to production based on the massive introduction of information technology into industry, large-scale automation business processes and the spread of artificial intelligence.

Industry 4.0 or the fourth industrial revolution (Table 3) promotes the transition to fully automated digital production, controlled by intelligent systems in real time in constant interaction with the external environment, overcoming the boundaries of a single enterprise, with the perspective of combining goods and services in an industrial network global. In a broad sense, Industry 4.0 represents a new level of production organization and value chain management throughout the entire product life cycle, and aims to achieve increased poductivity and increased worker safety through elimination of dangerous jobs.

Table 3. The first four successive industrial revolutions

| Industrial Revolution | Period | Innovation / breakthrough | Results |

| First | 1760 – 1820 /1840 | mechanisation, water power, steam power | transition from an agrarian economy to industrial production, development of transport |

| Second | 1871 – 1914 | mass production, assembly line, electricity | railways, electrification, flow production, division of labour |

| Third | since 1970 | computer and automation | automation and robotics |

| Fourth(Industry 4.0) | since 2011 | Cyber Physical Systems | distributed production, distributed energy, networked collective access and consumption, replacement of intermediaries with distributed networks, direct access of the producer to the consumer, sharing economy (car sharing, for example) |

Source: compiled by the author from (MEDIUM: Manufactory, 18.06.2018) and

(TADVISER, 17.10.2017)

The concept of “Industry 4.0” is based on four principles (Abele, 2016; Tarasov, 2018):

interoperability of humans, machines and cyber-physical systems (Smart Factories), which makes it possible to communicate directly via the Internet of Things and the Internet of Services;

virtualization and transparency of information, and the ability of systems to create a virtual copy of the Smart Factory which is created by linking sensor data (from monitoring physical processes) with virtual plant models and simulation models;

technical assistance of machines to humans to collect, combine and analyse large volumes of data and perform a number of tasks that are unsafe for humans and provide the derived insights immediately (Big Data);

the ability of cyber-physical systems within Smart Factories to make decisions independently and autonomously.

The main idea of cyber-physical systems is maximum automation, partial or complete exclusion of humans from production and business processes. The problem is that humans are always the weak link. The human factor is very often the cause of errors, inaccuracies, as a result of which the business suffers losses. Moreover, in some industries, human error can even lead to tragic consequences, for example, to injuries at work. Cyber-physical systems allow improving production processes, providing real-time data exchange between such elements as industrial equipment, logistics, business management systems and clients. In addition, cyber-physical systems allow automatic monitoring and control of the entire process, including adaptation of production to the current needs of clients.

According to the Industry 4.0 paradigm, in the future, factories and plants will be able to improve and modernize themselves, that is, without or with minimal human involvement. Business processes, logistics, and production cycles will be constantly optimized autonomously. Predictive analytics will play a significant role in this process. Based on the analysis of large amounts of data, it will be possible to predict the probability of a system element or an entire device breaking down, and replace the component before it completely fails.

An example of such a smart factory is Siemens Electronic Works in Amberg, Germany (Hessman, 2013), where human involvement is minimized and the smart system independently monitors the functioning of 1.6 billion components. It also sets production standards and manages logistics flows.

The introduction of the technologies of the fourth industrial revolution is radically changing the activities of industrial companies. Back in 2015, the McKinsey Global Institute (Manyika, 2015) predicted a significant gap in performance between companies that had introduced the technologies of the fourth industrial revolution and those lagging behind. Thus, according to the authors of the study, companies that are unable to respond to the current technological trend in a timely manner will miss out on a significant part of the benefits.

Also, in 2017, a study by the consulting company Pricewaterhouse Coopers (PWC, 2017) concluded that the introduction of technologies of the fourth industrial revolution affects productivity increases, allows for better response to customer requests, personalization of products, and reduction of logistics costs.

Same, in 2019, the World Economic Forum and McKinsey & Company (World Economic Forum, 2019) analysed the cases of lighthouse companies that implemented technologies of the fourth industrial revolution. The study concluded that the implementation of these technologies allows increasing production output by 10–200 %, achieve productivity growth by 5–160%, increase overall equipment efficiency by 3–50%, reduce quality costs by 5–40%, increase energy efficiency by 2–50%, speed up production cycles by 10–90%, speed up launching new products by 30-90%, reducing batch size by 50-90%, which makes it possible to make new products more personalized.

The experience of modern Smart Factories confirms the impact of Industry 4.0 technologies on the financial performance of industrial companies. Thus, the introduction of new technologies allows increasing revenue by increasing the speed of bringing new products to market and improving the quality of services provided, reducing costs by reducing labour costs, including line managers, repair and maintenance needs, launching production lines, internal warehouse logistics, and electricity.

Also, the introduction of new technologies allows increasing productivity by optimizing the loading and operating modes of production equipment, optimizing logistics and supply chains, improving key product quality characteristics, more accurately forecasting demand, reducing the time of design and bringing products to market, and improving after-sales service. The introduction of new technologies also allows replacing the labour of many workers and specialists and performing the operation more efficiently.

In addition, the experience of technologically advanced enterprises shows that the implementation of technologies of the fourth industrial revolution is achieved through the optimization of production business processes: servicing (design and prototyping, production planning, production analytics, logistics, technical control, occupational health and safety), auxiliary (maintenance and repair, management of tools and equipment, provision of all types of energy) and technological (harvesting, processing, assembling).

Beside these, Industry 4.0 technologies are designed to reduce time to market for new products, improve the effectiveness of customer interactions, promote economies of scale and more efficiently use resources.

Depending on the situation it is in, and the goals it pursues, each industrial enterprise have to adopt its own strategies for implementing the Industry 4.0 concept. When making these decisions, it is necessary to evaluate and appreciate:

strategic goals for the next few years;

technologies and systems that have already been implemented and are operating at the enterprise;

the efficiency of the technologies and systems that have already been implemented at the enterprise;

steps (stages) to be performed for a successful transformation;

the benefits that the enterprise wants to obtain.

In the same way, each enterprise must establish its strategic priorities and the sequence in which it will act.

As a result of such a strategic analysis, the enterprise will be able to formulate an operational digital transformation plan for all its structural units, indicating SMART (Specific, Measurable, Achievable, Relevant, and Time-Bound) goals.

According to the study “Industrie 4.0 Maturity Index” (Schuh Günther, Anderl Reiner, et al., 2017), there are 6 (six) stages in the Industry 4.0 development path: (Schuh Günther, Anderl Reiner, et al., 2017, pp. 15-18).

I. Computerisation – first stage – the enterprise uses different information technologies, separately from each other, mainly for more efficient performance of repetitive tasks. The used information technologies also help to reduce the cost of production and at the same time bring it to higher standards and greater accuracy. Same, a lot of equipment without a digital interface, controlled manually, continues to be used.

II. Connectivity – second stage – the separate (individually, by each structural units) implementation of information technologies is replaced by interconnected elements, but a full integration of the levels of IT and operational technologies has not yet been achieved. At his stage, manufacturing companies widely use business applications of operational technology systems that are interconnected and reflect the company’s key business processes.

Among these systems, in industry, the main ones are: (Zemsky, J., 2024)

PLM – Product Lifecycle Management systems aggregate, automate, and centralize the management of product data for distribution across the enterprise. The purpose of PLM is to manage the entire lifecycle of a product, from conception and design, through manufacturing, to after-sale service and even final disposal.

ERP – Enterprise Resource Planning systems manage a broad array of business processes across the organization. Domains like supply chain management, operations, personnel, and finance are integrated within ERP systems. Design, engineering, and manufacturing activities also interact with ERP in ways that are critical to the overall smooth operation of the enterprise.

MES – Manufacturing Execution Systems, are focused on the production process itself – the fabrication, assembly and quality control activities that result in a discrete product, ready to sell. By monitoring and controlling in-progress production flows, MES can capture data and provide critical, real-time feedback. The result is better-informed decision-making to optimize manufacturing operations.

These systems, if properly implemented and coordinated, can provide significant benefits, both when operated individually and when operating in an integrated manner. Simplified operations, increased efficiency and better quality – these are just a few of the many benefits available from integrated operational technology systems.

III. Visibility – third stage – enterprises widely use sensors that allow them to capture end-to-end processes with a large number of data entry points and record events in real time across the entire company, and not just in specific areas such as manufacturing floors, as it was previously. This makes the current digital enterprise model available at all stages of production.

This data is detailed enough to let observers know exactly what is going on at the factory at any given time, but they may not have the organization to make this possible. At this stage, the presence of the data itself is the only qualifying factor. However, the integration of existing data sources with sensors, as well as integration of PLM, ERP and MES systems can bring significant benefits and provide a comprehensive picture of the current state of production.

IV. Transparency – fourth stage – digital development is moving from increasing technical capabilities to using analytics. To achieve this, manufacturers must learn to interpret and understand the data they collect. Most shop control management software performs this type of analysis automatically, sorting and displaying relevant data in response to user queries. Digital transparency helps the company to understand why certain events occur and use this information to gain insights through root cause analysis, identifying semantic relationships, and aggregating data to obtain relevant information and contextualization. All this provides knowledge about all processes within the enterprise, this knowledge being necessary to support complex and rapid decision-making.

V. Predictive capacity – the fifth stage – manufacturers use the real-time data at their disposal to forecast the future of their production capabilities. This is done in order to imagine different scenarios, the probability of which can then be assessed. As a result, companies can anticipate future events and, as a result, take timely decisions and appropriate actions. This includes information about when downtime may occur, when quality control may fail, where the plant can save energy, and much more. This is another area where shop floor management software plays an important role in reducing the number of unexpected events such as breakdowns or deviations from plan, ensuring a more stable operation of the plant. For example, a company could look at recurring logistics problems, such as carrier breakdowns, before they happen and prevent them – in this case, by changing carriers.

VI. Adaptability the sixth stage – is a fundamental requirement for automated decisions and automated decision making. Digital systems in the enterprise have the ability to operate independently, using their analytical and predictive capabilities. Continuous adaptation allows the industrial enterprise to transfer responsibility for making certain decisions to IT systems in order to adapt as quickly as possible to a changing business environment. Digital systems can take steps to adapt to changing conditions as they evolve, organizing personnel and their responsibilities to manage routine operations as well as emergencies and emerging problems.

Finley, it should be noted that, in order to implement the concept of Industry 4.0, there are few developed technologies, but it is much more important to build on their basis a harmonious ecosystem both within an enterprise and along the entire value chain. Already today, individual business processes are successfully moving into the digital environment, but at the same time they remain “isolated islands” in a sea of analogue interactions. A deeper digital integration is hampered by “bottlenecks” – business processes that rely entirely on people and depend on their bandwidth and cognitive resources. There are many such “bottlenecks” in every industry and any digital transformation strategy should include their identification, analysis and development of specific measures to reduce “human dependency”.

Thus, investments of industrial companies in the technologies of the fourth industrial revolution allow changing the innovative behaviour of an industrial company and increasing the efficiency of production, expressed by increasing flexibility and adaptability, increasing the customization of goods and services, individualization and reduction of manufactured batches of goods, reducing the time of prototype development, launching new products on the market and increasing the overall level of technological development, accelerating the production cycle and increasing labour productivity, which ultimately leads to an increase in revenue and a decrease in cost.

Conclusion

The growth of the population’s well-being is closely linked to the capacity of society to produce values that satisfy or contribute to the satisfaction of individual and collective needs. A country is richer when it has developed value-producing capabilities. Industry is the economic branch, which, by its essence of combining economic factors (material resources acquired from nature or obtained through processing, human resources, financial and capital resources, informational resources) constitutes the driving force of economic and social development. A well-functioning and active industry ensures sustainable development and predictable well-being.

The industrial activity in the Republic of Moldova is carried out in the context of an ongoing demographic crisis and an increasing flow of emigrants. Thus, in the period 2014-2022, the number of permanent residents in the country decreased by about 12.42%, while the flow of emigration (temporary and permanent) increased almost 2-fold. Accordingly, the decrease in the number of people of working age has exacerbated the shortage of labour employed in the industry.

The comparative analysis of statistical data reveals a downward trend in labour productivity, the main cause being the decrease in tangible (physical, engineering structures, machines and equipment) and intangible (technologies, know-how) investments.

In this context, it is reasonable to conceive and promote the development of the industry of the Republic of Moldova in accordance with the paradigm of “Industry 4.0”, based on the digitalization and automation of production processes.

Thus, implementation of technologies of the fourth industrial revolution is achieved through the optimization of production business processes. Industry 4.0 or the fourth industrial revolution promotes the transition to fully automated digital production, controlled by intelligent systems in real time in constant interaction with the external environment, overcoming the boundaries of a single enterprise, with the perspective of combining goods and services in an industrial network global. In a broad sense, Industry 4.0 represents a new level of production organization and value chain management throughout the entire product life cycle, and aims to achieve increased productivity and increased worker safety through elimination of dangerous jobs.

There are six stages in the Industry 4.0 development path: Computerisation, Connectivity, Visibility, Transparency, Predictive capacity, and Adaptability. In order to implement the concept of Industry 4.0, there are few developed technologies, but it is much more important to build on their basis a harmonious ecosystem both within an enterprise and along the entire value chain.

A deeper digital integration is hampered by “bottlenecks” – business processes that rely entirely on people and depend on their bandwidth and cognitive resources. However, by implementing the Industry 4.0 paradigm, in the future, factories and plants will be able to pass these constraints and to improve and modernize themselves, without or with minimal human involvement in dangerous processes. Business processes, logistics, and production cycles will be constantly optimized autonomously.

Thus, investments of industrial companies in the technologies of the fourth industrial revolution allow changing the innovative behaviour of an industrial company and increasing the efficiency of production, expressed by increasing flexibility and adaptability, increasing the customization of goods and services, individualization and reduction of manufactured batches of goods, reducing the time of prototype development, launching new products on the market and increasing the overall level of technological development, accelerating the production cycle and increasing labour productivity, which ultimately leads to an increase in revenue and a decrease in cost.

These measures will allow to solve the problem of labour shortage observed in Moldova, as well as to bring the level of industrial and technological development to a globalised competitive level.